Offices Nationwide

The Decibel Scale

Gives an approx of human perception of loudness. This is because the human ear has a logarithmic response to changes in sound level...more

Air Testing & Leakage

Our engineers use Thermal camera and extensive knowledge of buildings to help find leakage areas within the building and can advice of these.

Cookstown - Fire Suppression Room Integrity Testing - 0141 894 0107

The office that covers this area is: Glasgow

Phone Number: 0141 894 0107 Email: cookstown@e2consultants.co.uk

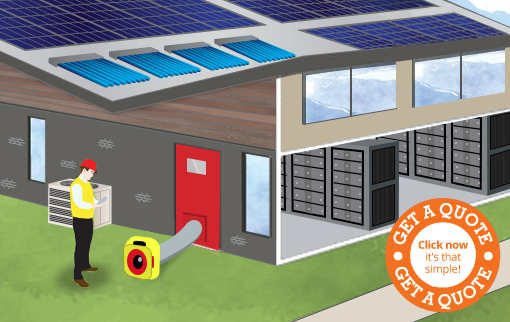

What is A Room Integrity Test and How Does It Work?

Room Integrity Testing is required for any gaseous fire suppression system. Gas fire suppression systems work by releasing a gas agent into an enclosure and the gas then either reacts with the fire or reduces the oxygen level which then suppresses or extinguishes the fire. For a fire suppression system to work correctly the enclosure needs to hold the gas for a set period of time.

Room Integrity Testing is used to determine if the room is capable of holding the gas from the fire suppression system successfully. On top of which, the test can predict how long it will take for the gas levels to be reduced to the point where a discharge of the system will be needed. Discharging a fire system can be both costly and disruptive.

Will The Test Disrupt My Business?

No - you and your staff can still work while testing is taking place. The only thing that may affect workflow is the door fan equipment that must be fixed to the main door and will in turn stop people being able to enter or leave the room during this time.

Testing Procedure

Upon arriving at site and unloading the equipment, one of our consultants will inspect the room where the test will take place. Room measurements will need to be taken at this time if they have not been done prior to our site visit. The door fan kit will be set-up by our consultant in the most appropriate door in the room, usually the main door. There will be no requirement for the removal of any doors to make room for our testing equipment as we aim to make as little impact on the environment as possible.

What are the Standards and Guidance?

The main standards that recommend Room Integrity Testing on commissioning of a system and the annual re-testing of an enclosure are BSEN15004, ISO14520, BAFE SP203-3 and NFPA 2001. These are UK and US national and international standards that provide guidance on how to carry out the test and the frequency of re-testing.

The test will depressurise and pressurise the room whilst using computer software to collect the data. Once complete, our consultant will check the data against target data provided by the client. If the result is lower than the target score then our consultantrs will beging to identify the problem areas.

All of our consultants are trained to use thermographic cameras to help identify these leakage areas, these images will be sent to the client with a full test report as well as the snag list. The snag list will outlineall the identified leakage areas that will need to be addressed along.

Will I Need To Re-Test The Room At A Later Date?

Any room, particularly those housing Electronic Data Processors, often get disturbed by service and general building work. General wear and tear from using a room can result in a small hole being made, or even if the room size changes, then another test will need to be perfomred. According to British Standards, a Room Integrity Test should be carried out at least once a year to ensure your gaseous fire suppression system will work correctly, should it ever need to be activated.

Our other services include:

Fire Suppression Room Integrity Testing can also be known as:

Fire Suppression Testing, Room Integrity Testing, Server Room Testing,

Copyright 2025 E2 Specialist Consultants Limited

Company No. 06728970