Offices Nationwide

• Glasgow

• Newcastle

• Manchester

• Portsmouth

• Wakefield

• Sheffield

• Birmingham

• Wrexham

• Cardiff

• Peterborough

• Milton Keynes

• London

• Plymouth

• Anglesey

• Glasgow

• Newcastle

• Manchester

• Portsmouth

• Wakefield

• Sheffield

Sound Insulation

Two parameters describe sound insulation; Dw and Rw. Dw is the insulation between rooms. Rw is the lab-tested insulation of a wall/floor...more

Sound Privacy

Privacy describes the perceived sound reduction across a wall, a function of both sound insulation and background noise...more

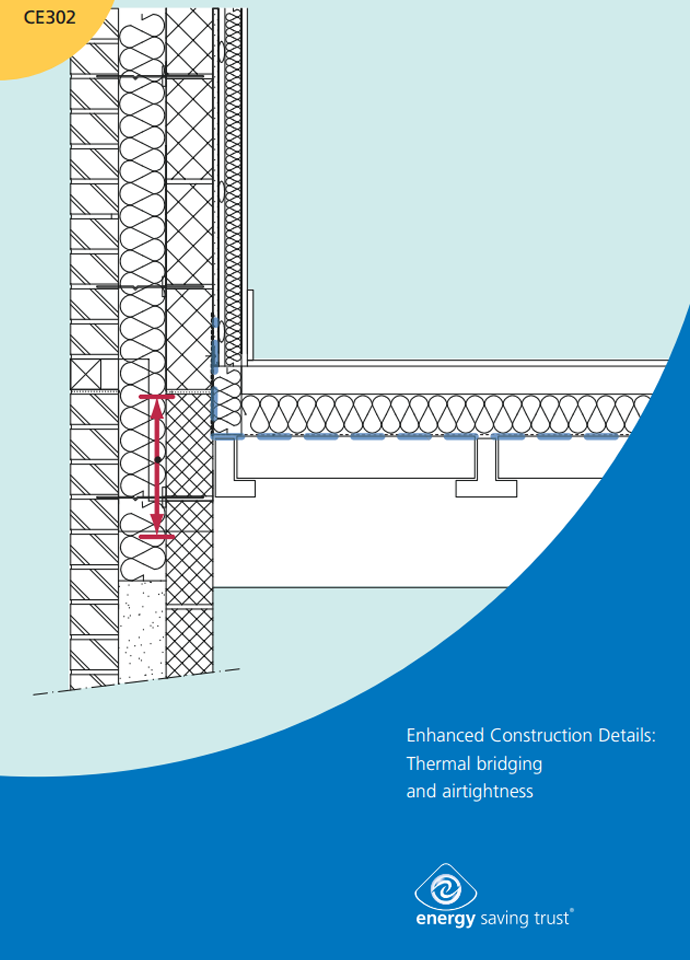

Thermal Bridging And Airtightness

Enhanced Construction Details

Harby - Server Room Testing - 0114 368 0192

The office that covers this area is: Sheffield

Phone Number: 0114 368 0192 Email: harby@e2consultants.co.uk

Our other services include:

Server Room Testing can also be known as:

Room Integrity Testing, Fire Suppression Testing, Fire Suppression Room Integrity Testing,

Copyright 2025 E2 Specialist Consultants Limited

Company No. 06728970